By clicking “Accept All Cookies” you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Privacy Policy

Silane Coating Market (By Type: Amino Silane Coating, Epoxy Silane Coating, Vinyl Silane Coating, Methacrylic Silane Coating, Mercapto Silane Coating, Urethane Silane Coating, and Isocyanate Silane Coating; By Application: Automotive, Construction, Electronics, Consumer Goods, Industrial Equipment, Medical Devices, and Others; By Region: North America, Europe, Asia Pacific, Latin America, and Middle East & Africa) Industry Size, Share, Growth, Trends 2025 to 2034

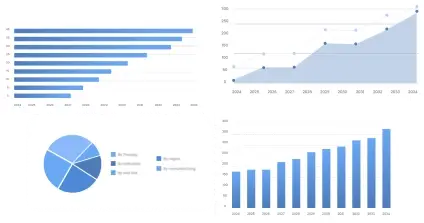

The global silane coating market size was valued at USD 1,131 million in 2024, is projected to reach approximately USD 2,288 million by 2034. This growth, fueled by increasing use in protective coatings, automotive, and construction applications, is expected at a CAGR of 7.3%.

| Reports Attributes | Statistics |

| Market Size in 2024 | USD 1,131 Million |

| Market Size in 2025 | USD 1,214 Million |

| Market Size in 2031 | USD 1,852 Million |

| Market Size by 2034 | USD 2,288 Million |

| CAGR 2025 to 2034 | 7.3% |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

The silane coating market is expanding at a decent pace due to the rising demand for protection against chemical bonds on glass and metals. Multiple sectors, like construction, are using them for enhancing the durability of concrete, facades, and bridges. The emerging economies like India and China are helping in generating more opportunities for silane coating. The price volatility of raw materials may disrupt the supply chain in rural economies due to increased investment requirements. The rapid investments in the automotive sector are expected to create multiple business opportunities as they are using silane coating in metal parts, plastic components, and glass. The emergence of nanotechnology in silane coating is expected to make them more durable and superior for use in these applications.

The silane coating market is expected to gain more popularity due to the integration of artificial intelligence AI and machine learning ML, as the technology aids in designing coatings with a more precise use of properties. Additionally, AI algorithms are being used during the production process for detecting any errors or defects.

| Regions | Shares (%) |

| North America | 25% |

| Asia Pacific | 42% |

| Europe | 22% |

| LAMEA | 11% |

| Segments | Shares (%) |

| Amino Silane Coating | 25% |

| Epoxy Silane Coating | 18% |

| Vinyl Silane Coating | 15% |

| Methacrylic Silane Coating | 10% |

| Mercapto Silane Coating | 10% |

| Urethane Silane Coating | 12% |

| Isocyanate Silane Coating | 10% |

| Segments | Shares (%) |

| Automotive | 25% |

| Construction | 20% |

| Electronics | 15% |

| Consumer Goods | 10% |

| Industrial Equipment | 15% |

| Medical Devices | 10% |

| Others | 5% |

Published by Saurabh Bidwai

| Type | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Amino Silane Coating | 282.75 | 300.96 | 320.33 | 340.92 | 362.81 | 386.08 | 410.81 | 437.09 | 465.02 | 494.71 | 526.24 |

| Epoxy Silane Coating | 203.58 | 219.65 | 236.99 | 255.69 | 275.85 | 297.60 | 321.05 | 346.34 | 373.61 | 403.02 | 434.72 |

| Vinyl Silane Coating | 169.65 | 182.03 | 195.32 | 209.58 | 224.88 | 241.30 | 258.91 | 277.81 | 298.09 | 319.85 | 343.20 |

| Methacrylic Silane Coating | 113.10 | 122.57 | 132.82 | 143.91 | 155.92 | 168.91 | 182.96 | 198.17 | 214.63 | 232.43 | 251.68 |

| Mercapto Silane Coating | 113.10 | 121.36 | 130.22 | 139.72 | 149.92 | 160.86 | 172.61 | 185.21 | 198.73 | 213.24 | 228.80 |

| Urethane Silane Coating | 135.72 | 145.63 | 156.26 | 167.67 | 179.90 | 193.04 | 207.13 | 222.25 | 238.47 | 255.88 | 274.56 |

| Isocyanate Silane Coating | 113.10 | 121.36 | 130.22 | 139.72 | 149.92 | 160.86 | 172.61 | 185.21 | 198.73 | 213.24 | 228.80 |

| Application | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Automotive | 282.75 | 300.96 | 320.33 | 340.92 | 362.81 | 386.08 | 410.81 | 437.09 | 465.02 | 494.71 | 526.24 |

| Construction | 226.20 | 243.93 | 263.03 | 283.63 | 305.84 | 329.77 | 355.57 | 383.38 | 413.36 | 445.66 | 480.48 |

| Electronics | 169.65 | 184.46 | 200.53 | 217.96 | 236.87 | 257.38 | 279.62 | 303.74 | 329.89 | 358.24 | 388.96 |

| Consumer Goods | 113.10 | 121.36 | 130.22 | 139.72 | 149.92 | 160.86 | 172.61 | 185.21 | 198.73 | 213.24 | 228.80 |

| Industrial Equipment | 169.65 | 180.82 | 192.72 | 205.39 | 218.88 | 233.25 | 248.56 | 264.85 | 282.19 | 300.66 | 320.32 |

| Medical Devices | 113.10 | 121.36 | 130.22 | 139.72 | 149.92 | 160.86 | 172.61 | 185.21 | 198.73 | 213.24 | 228.80 |

| Others | 56.55 | 60.68 | 65.11 | 69.86 | 74.96 | 80.43 | 86.30 | 92.60 | 99.36 | 106.62 | 114.40 |

| Region | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| North America | 282.75 | 302.18 | 322.93 | 345.11 | 368.80 | 394.12 | 421.16 | 450.06 | 480.92 | 513.90 | 549.12 |

| Europe | 248.82 | 265.77 | 283.87 | 303.19 | 323.83 | 345.86 | 369.38 | 394.49 | 421.30 | 449.93 | 480.48 |

| Asia Pacific | 475.02 | 513.34 | 554.72 | 599.40 | 647.66 | 699.76 | 756.02 | 816.77 | 882.35 | 953.16 | 1,029.61 |

| Latin America | 67.86 | 71.60 | 75.52 | 79.64 | 83.96 | 88.48 | 93.21 | 98.16 | 103.34 | 108.75 | 114.40 |

| Middle East and Africa | 56.55 | 60.68 | 65.11 | 69.86 | 74.96 | 80.43 | 86.30 | 92.60 | 99.36 | 106.62 | 114.40 |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Amino Silane Coating | 282.75 | 300.96 | 320.33 | 340.92 | 362.81 | 386.08 | 410.81 | 437.09 | 465.02 | 494.71 | 526.24 |

| Epoxy Silane Coating | 203.58 | 219.65 | 236.99 | 255.69 | 275.85 | 297.60 | 321.05 | 346.34 | 373.61 | 403.02 | 434.72 |

| Vinyl Silane Coating | 169.65 | 182.03 | 195.32 | 209.58 | 224.88 | 241.30 | 258.91 | 277.81 | 298.09 | 319.85 | 343.20 |

| Methacrylic Silane Coating | 113.10 | 122.57 | 132.82 | 143.91 | 155.92 | 168.91 | 182.96 | 198.17 | 214.63 | 232.43 | 251.68 |

| Mercapto Silane Coating | 113.10 | 121.36 | 130.22 | 139.72 | 149.92 | 160.86 | 172.61 | 185.21 | 198.73 | 213.24 | 228.80 |

| Urethane Silane Coating | 135.72 | 145.63 | 156.26 | 167.67 | 179.90 | 193.04 | 207.13 | 222.25 | 238.47 | 255.88 | 274.56 |

| Isocyanate Silane Coating | 113.10 | 121.36 | 130.22 | 139.72 | 149.92 | 160.86 | 172.61 | 185.21 | 198.73 | 213.24 | 228.80 |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Automotive | 282.75 | 300.96 | 320.33 | 340.92 | 362.81 | 386.08 | 410.81 | 437.09 | 465.02 | 494.71 | 526.24 |

| Construction | 226.20 | 243.93 | 263.03 | 283.63 | 305.84 | 329.77 | 355.57 | 383.38 | 413.36 | 445.66 | 480.48 |

| Electronics | 169.65 | 184.46 | 200.53 | 217.96 | 236.87 | 257.38 | 279.62 | 303.74 | 329.89 | 358.24 | 388.96 |

| Consumer Goods | 113.10 | 121.36 | 130.22 | 139.72 | 149.92 | 160.86 | 172.61 | 185.21 | 198.73 | 213.24 | 228.80 |

| Industrial Equipment | 169.65 | 180.82 | 192.72 | 205.39 | 218.88 | 233.25 | 248.56 | 264.85 | 282.19 | 300.66 | 320.32 |

| Medical Devices | 113.10 | 121.36 | 130.22 | 139.72 | 149.92 | 160.86 | 172.61 | 185.21 | 198.73 | 213.24 | 228.80 |

| Others | 56.55 | 60.68 | 65.11 | 69.86 | 74.96 | 80.43 | 86.30 | 92.60 | 99.36 | 106.62 | 114.40 |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| North America | 282.75 | 302.18 | 322.93 | 345.11 | 368.80 | 394.12 | 421.16 | 450.06 | 480.92 | 513.90 | 549.12 |

| Europe | 248.82 | 265.77 | 283.87 | 303.19 | 323.83 | 345.86 | 369.38 | 394.49 | 421.30 | 449.93 | 480.48 |

| Asia Pacific | 475.02 | 513.34 | 554.72 | 599.40 | 647.66 | 699.76 | 756.02 | 816.77 | 882.35 | 953.16 | 1,029.61 |

| Latin America | 67.86 | 71.60 | 75.52 | 79.64 | 83.96 | 88.48 | 93.21 | 98.16 | 103.34 | 108.75 | 114.40 |

| Middle East and Africa | 56.55 | 60.68 | 65.11 | 69.86 | 74.96 | 80.43 | 86.30 | 92.60 | 99.36 | 106.62 | 114.40 |

To get full access to our Market Insights, you need a Professional Account or a Business Suite.

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Our customers work more efficiently and benefit from