Last Updated: 21 Jul 2025

Source: Statifacts

By clicking “Accept All Cookies” you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Privacy Policy

Oral Irrigator Market (By Product Type: Countertop, Cordless; By Application: Home, Dentistry; By Distribution Channel: Online, Offline; By Region: North America, Europe, Asia Pacific, Latin America, Middle East and Africa) Industry Size, Share, Growth, Trends 2025 to 2034.

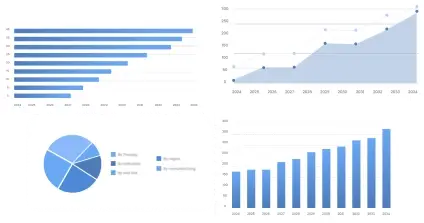

The global catheter manufacturing technologies market size was estimated at USD 35.76 billion in 2024 and is projected to be worth around USD 150.63 billion by 2034, growing at a CAGR of 15.46% from 2025 to 2034. The catheter manufacturing market is propelled by rising chronic disease prevalence, particularly cardiovascular, neurological, and geriatric populations, which fuel demand for cardiovascular, IV, diagnostic, and specialty catheters.

| Industry Worth | Details |

| Market Size in 2025 | USD 40.99 Billion |

| Market Size by 2034 | USD 150.63 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 15.46% |

Catheter manufacturing encompasses extrusion, reinforcement, and finishing processes that produce minimally invasive shafts used in cardiovascular, neurovascular, urology, and interventional procedures. Putnam Plastics, with over 40 years in medical extrusion, offers single and multi-lumen, co-extruded, braided, coiled, and wire-reinforced tubing, all critical for feeding into technologies such as balloon catheters, guidewires, dilators, and introducers. These shafts are further finished via laser welding, radio-frequency welding (RF welding), tipping, hole punching, and reflow assembly to create catheters suitable for dilators and introducers. These shafts are further finished via laser welding, RF welding, tipping hole punching, and reflow assembly to create catheters suitable for diagnostics, drug delivery, and structural heart interventions, supporting both original equipment manufacturer (OEM) and contract manufacturing markets worldwide.

The catheter manufacturing technologies market drivers are high demand for minimally invasive procedures, which widely involve the use of catheters. These are essential tools used by healthcare professionals to access and treat various parts of the patient’s body through tiny incisions. These significantly cut down on the trauma from surgery, improving recovery time and reducing complications. They are essential tools for accessing and treating various parts of the body through small incisions, offering benefits like reduced trauma and faster recovery.

Demand for diagnostic services has significantly propelled catheter innovation by introducing intelligent design and autonomous capabilities.

Manufacturing confronts intricacy as catheters now often feature multi-lumen shaft steerable tips, embedded sensors or conductors, balloons, and hybrid material layering, all packed profiles less than 2mm wide. Assuring biocompatibility, structural integrity, torque, and flexibility across these miniaturized, multi-functional interfaces requires rigorous validation of material behavior, not only during extrusion but also post-processing steps like laser cutting, bonding, and sterilization. Missteps in material selection or process tuning can lead to defects such as micro cracks or delamination, staling development, and significantly raising production costs.

Catheter systems, particularly those intended for class 3 use, are subject to stringent regulatory scrutiny. Full traceability of all components, ISO 13485-aligned documentation, and sub-millimeter dimensional control. Any single deviation in material batch ID, bonding strength, or dimensional tolerance can trigger extensive rework or a full clinical hold. OEMs must manage exhaustive quality control, batch tracking, and validation protocols, all while coordinating with sterilizing partners to assure materials remain reliable under gamma, e-beam, or EtO sterilization, any of which can degrade polymers if not pre-qualified. This regulatory overhead slows time to market and elevates operational costs.

Advanced materials such as hydrophilic, antimicrobial, and biodegradable polymers are creating pivotal opportunities. Hydrophilic coatings reduce insertion friction, dramatically improving patient comfort, while antimicrobial surfaces lower the risk of catheter-associated infections. Biodegradable catheters, which dissolve safely post-use use offer environmental and procedural advantages by eliminating removal steps. These material enhancements position manufacturers to meet rising demands for safer, more sustainable devices and align with tightening regulatory and infection control standards.

The integration of sensors and electronics into catheters paves the way for real physiological monitoring procedures. Smart catchers capable of measuring parameters like pressure, temperature, or pH and wirelessly transmitting data are merging tools in cardiology, urology, and neurology. These devices not only improve diagnostic accuracy and procedural precision but also enable remote patient monitoring and minimally invasive treatments. This trend heralds the transition from passive tools to intelligent platforms, opening new development and clinical adoption possibilities.

“We could not be more excited about the opportunity that Kardionav brings…combining vector technology with imaging…today’s ablation techniques in the ventricle leave much to be desired…without precise localization…advanced catheters do little to bring about better patient outcomes.”

“We are very excited… have received positive feedback… confirmed interest…and have already received our first order from the EU.”

By manufacturing process, the braiding segment dominated the catheter manufacturing technologies market. Braided catheter shafts remain the cornerstone of catheter technology due to their exceptional torque control and kink resistance. Studies show that metallic braids significantly outperform unbraided alternatives in maintaining lumen integrity under torsion and bends ideal for navigating complex vascular pathways. Variations in braid patterns, materials, and densities enable manufacturers to optimize flexibility, push ability, and imaging compatibility. This versatility explains why braided catheters continue to dominate high-performance applications in cardiovascular, neurovascular, and interventional oncology procedures, acting as the industry benchmark for reliability and mechanical efficiency.

By manufacturing process, the laser welding segment is expected to see significant growth in the forecast period. Laser welding is rapidly gaining ground as the go-to finishing method due to its precision, minimal thermal impact, and process efficiency. Short, high-intensity laser pulses enable flawless attachment of pull wire bands, radiopaque markers, and tube seams with no filler or contamination. Crucially, the narrow heat-affected zones preserve the integrity of adjacent polymer and delicate sensor-equipped components. The process scales seamlessly from prototypes to mass production with consistent cycle times, driving its swift adoption, especially in complex, miniaturized steerable catheters that demand both strength and fine feature assembly.

Although not the market leader, coil reinforcement remains a notable and adaptable option in the catheter shaft space. Spiral metal coils offer excellent axial strength and pushability while maintaining flexibility by alternating coil density and material's valuable traits for instruments requiring deflection, such as steerable catheters used in electrophysiology and structural heart procedures. Hybrid designs combining braiding or laser-cut hypo tubes with coils further allow customization of mechanical properties, offering a balance of torque response and tractability. Such hybrid approaches position coiling as a strategic reinforcement choice within a segment focused on tailored mechanical performance.

North America

North America retains leadership in the global catheter manufacturing technologies market with a significant share in 2024. This market dominance stems from its advanced hospital networks, early adoption of cutting-edge technologies, and favourable reimbursement policies such as expedited Food and Drug Administration (FDA) Breakthrough Device pathways and expanded Medicare coverage, which encourage the uptake of premium catheter systems. The region’s stable regulatory landscape and willingness among providers to invest in next-generation catheters assure it remains the primary testing ground and commercialization hub for innovative devices.

Asia Pacific

Asia Pacific is set to experience the highest growth between the forecast period between 2025 and 2034. The region’s growth is expected to be fuelled by the modernization of health systems, rising surgical volumes, and expanding government healthcare investment. Significant public and private spending on manufacturing and technology transfers is driving rapid expansion. Moreover, increasing disposable income, expanding insurance coverage, and growing prevalence of chronic diseases are fuelling demand, making Asia Pacific the fastest rising region in catheter technology adoption.

The catheter manufacturing technologies industry is moderately concentrates, dominated by several key players that leverage advanced capabilities, but also features smaller specialized firms, creating a competitive yet collaborative landscape.

Resonetics is a global leader in laser micro manufacturing and contract manufacturing for the life sciences sector. Operating 14-17 facilities across the U.S., Canada, Costa Rica, Israel, and Switzerland, it offers precision laser cutting, welding, nitinol processing, microfluidics, sensor integration, and custom laser systems.

MET specializes in custom thermoplastic tubing extrusion for medical devices. The company operates multiple U.S. facilities and offers single/ multi-lumen, co-extrusion, bump profiles, radiopaque compound, and tight-tolerance tubing starting from 0.002 I.D. MET serves startups to major OEMs and supports rapid delivery through “Express Tubing” services.

ICU Medical is a prominent medical technology company with ~12,000 employees, offering IV therapy, infusion systems, closed system connectors, oncology delivery sets, hemodynamic monitoring, and sensor catheters.

| Regions | Shares (%) |

| North America | 40% |

| Asia Pacific | 30% |

| Europe | 20% |

| LAMEA | 10% |

| Segments | Shares (%) |

| Braiding | 30% |

| Coiling | 25% |

| RF Welding | 15% |

| Laser Welding | 20% |

| Reflow Technology | 10% |

Published by Ajit Bansod

| Manufacturing Process | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Braiding | 32 | 32.20 | 32.40 | 32.60 | 32.80 | 33 | 33.20 | 33.40 | 33.60 | 33.80 | 34 |

| Coiling | 24 | 24.10 | 24.20 | 24.30 | 24.40 | 24.50 | 24.60 | 24.70 | 24.80 | 24.90 | 25 |

| RF Welding | 18 | 17.90 | 17.80 | 17.70 | 17.60 | 17.50 | 17.40 | 17.30 | 17.20 | 17.10 | 17 |

| Laser Welding | 14 | 14.10 | 14.20 | 14.30 | 14.40 | 14.50 | 14.60 | 14.70 | 14.80 | 14.90 | 15 |

| Reflow Technology | 12 | 11.70 | 11.40 | 11.10 | 10.80 | 10.50 | 10.20 | 9.90 | 9.60 | 9.30 | 9 |

| Region | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| North America | 38 | 37.80 | 37.60 | 37.40 | 37.20 | 37 | 36.80 | 36.60 | 36.40 | 36.20 | 36 |

| Asia Pacific | 30 | 30.30 | 30.60 | 30.90 | 31.20 | 31.50 | 31.80 | 32.10 | 32.40 | 32.70 | 33 |

| Europe | 22 | 21.90 | 21.80 | 21.70 | 21.60 | 21.50 | 21.40 | 21.30 | 21.20 | 21.10 | 21 |

| LAMEA | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

Last Updated: 21 Jul 2025

Source: Statifacts

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Braiding | 32 | 32.20 | 32.40 | 32.60 | 32.80 | 33 | 33.20 | 33.40 | 33.60 | 33.80 | 34 |

| Coiling | 24 | 24.10 | 24.20 | 24.30 | 24.40 | 24.50 | 24.60 | 24.70 | 24.80 | 24.90 | 25 |

| RF Welding | 18 | 17.90 | 17.80 | 17.70 | 17.60 | 17.50 | 17.40 | 17.30 | 17.20 | 17.10 | 17 |

| Laser Welding | 14 | 14.10 | 14.20 | 14.30 | 14.40 | 14.50 | 14.60 | 14.70 | 14.80 | 14.90 | 15 |

| Reflow Technology | 12 | 11.70 | 11.40 | 11.10 | 10.80 | 10.50 | 10.20 | 9.90 | 9.60 | 9.30 | 9 |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| North America | 38 | 37.80 | 37.60 | 37.40 | 37.20 | 37 | 36.80 | 36.60 | 36.40 | 36.20 | 36 |

| Asia Pacific | 30 | 30.30 | 30.60 | 30.90 | 31.20 | 31.50 | 31.80 | 32.10 | 32.40 | 32.70 | 33 |

| Europe | 22 | 21.90 | 21.80 | 21.70 | 21.60 | 21.50 | 21.40 | 21.30 | 21.20 | 21.10 | 21 |

| LAMEA | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

Rising demand from minimally invasive procedures, such as neurovascular, cardiovascular, and urologic interventions, has driven the need for catheters with multi-lumen shafts, embedded sensors, steerable tips, and flexible material assemblies.

Braided tubing remains the dominant manufacturing method, prized for flexibility, kink resistance, and torque control. Meanwhile, laser welding is emerging rapidly for its precision, low thermal stress, and strong micro-scale joints.

What are the primary challenges in catheter manufacturing? Manufacturers must navigate extreme design complexity, including miniaturization, biocompatibility of advanced polymers (e.g., PEBAX®, TPU), and integration of electronics, under stringent quality and regulatory standards such as ISO 13485.

Innovations like AI-aided catheter design, multi-material extrusion, smart sensor integration, and advanced bonding methods (e.g., RF welding, reflow lamination) are boosting performance, reducing infection risk, and enhancing fabrication precision.

Opportunities include enhanced infection-reducing designs like ultrasonic friction control, partnerships between OEMs and extrusion specialists for rapid prototyping, and robotics acquisitions such as Stereotaxis integrating electrophysiology catheter know-how to scale advanced capabilities.

To get full access to our Market Insights, you need a Professional Account or a Business Suite.

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Our customers work more efficiently and benefit from