By clicking “Accept All Cookies” you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Privacy Policy

Automotive Battery X-Ray Imaging Inspection Market (By Type: Online Devices, Offline Devices; By Application: Lithium Iron Phosphate Battery, Lithium Manganese Oxide Battery, Ternary Polymer Lithium Battery, Other; By Region: North America, Asia-Pacific, Europe, Latin America, Middle East & Africa) Industry Size, Share, Growth, Trends 2025 to 2034.

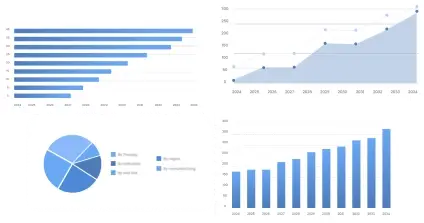

The global automotive battery X-ray imaging inspection market, valued at USD 1,321 million in 2024, is projected to reach USD 2,648 million by 2034, growing at a CAGR of 7.2% driven by increasing demand for advanced safety and quality control in automotive battery manufacturing.

| Reports Attributes | Statistics |

| Market Size in 2024 | USD 1,321 Million |

| Market Size in 2025 | USD 1,416 Million |

| Market Size in 2031 | USD 2,149 Million |

| Market Size by 2034 | USD 2,648 Million |

| CAGR 2025 to 2034 | 7.2% |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

The trend of increasing EV production, building gigafactories, and maintaining high-performing safety standards is a key reason why advanced inspection technologies using imaging are being adopted by the automotive industry. As the trend of global electric vehicles becomes more rapid, the integrity, performance, and safety of lithium-ion batteries have become a priority for automobile manufacturers and battery manufacturers. X-ray imaging inspection systems enable the detection of internal defects, electrode misalignment, and material inconsistencies that may lead to a loss of battery reliability or cause safety issues, such as overheating and short-circuiting.

The automotive battery X-ray imaging inspection market will grow faster as manufacturers adopt AI-driven inspections to improve accuracy, speed, and automation. Through the application of artificial intelligence AI-based analytics, these systems can automatically detect defects, anticipate performance problems, and streamline the imaging process, making it more accurate and consistent. It minimizes operational expenses and decreases production cycles. Also, EV infrastructure development, including machine vision and digital inspection technologies, is opening enormous opportunities for innovation.

| Regions | Shares (%) |

| North America | 35% |

| Asia Pacific | 40% |

| Europe | 20% |

| Latin America | 3% |

| Middle East & Africa | 2% |

| Segments | Shares (%) |

| Online Devices | 60% |

| Offline Devices | 40% |

| Segments | Shares (%) |

| Lithium Iron Phosphate Battery | 40% |

| Lithium Manganese Oxide Battery | 35% |

| Ternary Polymer Lithium Battery | 20% |

| Other | 5% |

Published by Yogesh Kulkarni

| Type | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Online Devices | 792.60 | 846.83 | 904.77 | 966.66 | 1,032.77 | 1,103.39 | 1,178.82 | 1,259.40 | 1,345.47 | 1,437.40 | 1,535.60 |

| Offline Devices | 528.40 | 569.28 | 613.30 | 660.71 | 711.77 | 766.76 | 825.98 | 889.75 | 958.42 | 1,032.37 | 1,111.99 |

| Application | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lithium Iron Phosphate Battery | 528.40 | 563.61 | 601.16 | 641.19 | 683.86 | 729.36 | 777.86 | 829.57 | 884.69 | 943.45 | 1,006.08 |

| Lithium Manganese Oxide Battery | 462.35 | 494.22 | 528.29 | 564.70 | 603.61 | 645.20 | 689.65 | 737.16 | 787.93 | 842.19 | 900.18 |

| Ternary Polymer Lithium Battery | 264.20 | 290.30 | 318.80 | 349.89 | 383.80 | 420.78 | 461.10 | 505.05 | 552.93 | 605.09 | 661.90 |

| Other | 66.05 | 67.98 | 69.82 | 71.59 | 73.27 | 74.81 | 76.19 | 77.37 | 78.34 | 79.04 | 79.43 |

| Region | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| North America | 462.35 | 492.81 | 525.25 | 559.82 | 596.63 | 635.85 | 677.62 | 722.11 | 769.50 | 819.96 | 873.70 |

| Asia Pacific | 528.40 | 569.28 | 613.30 | 660.71 | 711.77 | 766.76 | 825.98 | 889.75 | 958.42 | 1,032.36 | 1,111.99 |

| Europe | 264.20 | 283.22 | 303.61 | 325.47 | 348.91 | 374.03 | 400.96 | 429.83 | 460.78 | 493.95 | 529.52 |

| Latin America | 39.63 | 42.48 | 45.54 | 48.82 | 52.34 | 56.10 | 60.14 | 64.47 | 69.12 | 74.09 | 79.43 |

| Middle East & Africa | 26.42 | 28.32 | 30.37 | 32.55 | 34.89 | 37.41 | 40.10 | 42.99 | 46.07 | 49.41 | 52.95 |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Online Devices | 792.60 | 846.83 | 904.77 | 966.66 | 1,032.77 | 1,103.39 | 1,178.82 | 1,259.40 | 1,345.47 | 1,437.40 | 1,535.60 |

| Offline Devices | 528.40 | 569.28 | 613.30 | 660.71 | 711.77 | 766.76 | 825.98 | 889.75 | 958.42 | 1,032.37 | 1,111.99 |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lithium Iron Phosphate Battery | 528.40 | 563.61 | 601.16 | 641.19 | 683.86 | 729.36 | 777.86 | 829.57 | 884.69 | 943.45 | 1,006.08 |

| Lithium Manganese Oxide Battery | 462.35 | 494.22 | 528.29 | 564.70 | 603.61 | 645.20 | 689.65 | 737.16 | 787.93 | 842.19 | 900.18 |

| Ternary Polymer Lithium Battery | 264.20 | 290.30 | 318.80 | 349.89 | 383.80 | 420.78 | 461.10 | 505.05 | 552.93 | 605.09 | 661.90 |

| Other | 66.05 | 67.98 | 69.82 | 71.59 | 73.27 | 74.81 | 76.19 | 77.37 | 78.34 | 79.04 | 79.43 |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| North America | 462.35 | 492.81 | 525.25 | 559.82 | 596.63 | 635.85 | 677.62 | 722.11 | 769.50 | 819.96 | 873.70 |

| Asia Pacific | 528.40 | 569.28 | 613.30 | 660.71 | 711.77 | 766.76 | 825.98 | 889.75 | 958.42 | 1,032.36 | 1,111.99 |

| Europe | 264.20 | 283.22 | 303.61 | 325.47 | 348.91 | 374.03 | 400.96 | 429.83 | 460.78 | 493.95 | 529.52 |

| Latin America | 39.63 | 42.48 | 45.54 | 48.82 | 52.34 | 56.10 | 60.14 | 64.47 | 69.12 | 74.09 | 79.43 |

| Middle East & Africa | 26.42 | 28.32 | 30.37 | 32.55 | 34.89 | 37.41 | 40.10 | 42.99 | 46.07 | 49.41 | 52.95 |

To get full access to our Market Insights, you need a Professional Account or a Business Suite.

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Our customers work more efficiently and benefit from