01 July 2025

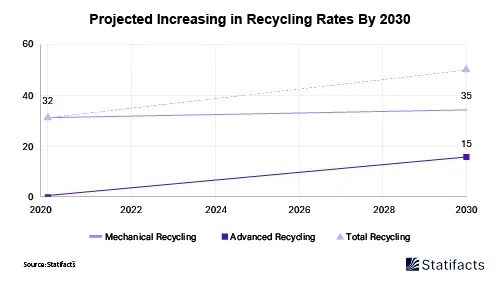

LyondellBasell, one of the world's largest chemical companies, announced a strategic alliance with Technip Energies today to build an advanced recycling plant in Ferrara, Italy. The partnership represents a breakthrough in the shift towards the circular economy in Europe's petrochemicals industry as companies push to achieve tight sustainability goals and tap into expanding demand for recycled plastics. According to the European Plastics Recyclers Association, future advanced recycling technologies will be able to complement mechanical recycling and boost the total recycling rate from the current 32% up to more than 50% by 2030. The Circular Economy Action Plan of the European Commission and the newly launched Clean Industrial Deal further enhance the regulatory environment backing such innovations.

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form

URL TO BE USED AS REFERENCE LINK:

Placeholder content for this accordion, which is intended to demonstrate the .accordion-flush class. This is the first item's

accordion body.

Placeholder content for this accordion, which is intended to demonstrate the .accordion-flush class. This is the second item's

accordion body. Let's imagine this being filled with some actual content.

Placeholder content for this accordion, which is intended to demonstrate the .accordion-flush class. This is the third

item's accordion body. Nothing more exciting happening here in terms of content, but just filling up the space to make it look, at least at

first glance, a bit more representative of how this would look in a real-world application.

Do you still any question?

Feel free to contact us anytime using our contact form or visit our FAQ page.

Your contact to the Infographics Newsroom