By clicking “Accept All Cookies” you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Privacy Policy

US Primary Packaging Market (By Packaging Type: Bottles, Cans, Cartons, Pouches, Tetra Packs, Bag-in-Box, Kegs and Barrels; By Application: Food & Beverage, Personal Care, Pharmaceuticals, Industrial; By Distribution: Retail, E-commerce, Supermarkets) Industry Size, Share, Growth, Trends 2025 to 2034.

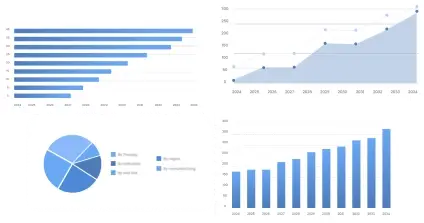

The US Primary Packaging market size was estimated at USD 35.88 billion in 2024 and is projected to surpass around USD 67.96 billion by 2034, growing at a CAGR of 6.59% from 2025 to 2034. The U.S. primary packaging industry is booming due to consumer demand for convenience, changing lifestyles associated with heightened awareness of sustainability, and product safety. The food and beverage, and pharmaceutical industries are seeking packaging options that provide safety, sustainability, and in some cases, sustainability via extended shelf-life. The industry is examining more lightweight, flexible, and able to have less weight and lower space requirements when stored or transported out of the packaging. The push for investment in smart and recyclable packaging options has also influenced the industry.

| Reports Attributes | Statistics |

| Market Size in 2024 | USD 35.88 Billion |

| Market Size in 2025 | USD 37.93 Billion |

| Market Size in 2030 | USD 51.36 Billion |

| Market Size by 2034 | USD 67.96 Billion |

| CAGR 2025 to 2034 | 6.59% |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

Primary packaging is an important part of many different products across industries. Primary packaging in food and beverages helps to maintain freshness, cleanliness, and convenience in storage and use. In pharmaceuticals, primary packaging supports prescribed dosage, sterility, and various safety and regulatory compliance considerations. For personal care and cosmetic products, primary packaging creates protection and incorporates branding with functional and aesthetic creativity. For cleaning products, primary packaging incorporates the utilitarian aspects of safety and protection against leaks. In e-commerce, the U.S. primary packaging market must survive transit while maintaining product properties, physical integrity, and attractiveness to the end user. Each of these applications affects and influences consumer actions, logistics, and supply chain considerations, and provides visual references, cues, and opportunities for brands. Primary packaging creates interactions between products and users, whether those products are resealable bags, tamper-evident bottles, or biodegradable cartons. Primary packaging is an important contributor to the performance of an individual product.

AI is leveraging the U.S. primary packaging industry to increase efficiency, quality, and sustainability. In the pharmaceutical space, U.S. manufacturers now use machine-learning vision systems that help reduce mis-ejects and achieve packaging integrity. In terms of next-generation packaging, AI is part of the design and procurement process and uses predictive analytics to guide where to utilize materials and to eliminate waste in supply chains. The National Association of Manufacturers reports in May 2024 that AI (i.e., machine learning, vision, and NLP) is reshaping how packaging operations are conducted, permitting more intelligent production lines and greater precision. North America is the global leader in development and deployment, and U.S. companies are at the forefront of AI-based control, monitoring, and customization, responding to new sustainability mandates, increasing consumer expectations, and the demand for improved cost efficiencies.

The market trends in the U.S. primary packaging market are shaped by e-commerce and mailer demand, Sustainability regulation in different states, and & the adoption of smart packaging in various industries.

E-commerce and mailer demand

The tremendous rise of e-commerce in the United States serves as a major factor in primary packaging. More parcels point towards more protective, lightweight mailer packaging requirements in the coming years. Consumers desire fast deliveries with minimal damage and environmentally friendly packaging options. As a result, packaging companies are competing with one another to develop mailers that are durable and sustainable, such as paper and insulated mailers, while maintaining environmentally sustainable packaging options for consumers. While packaging for consumers may differ from the logistical requirements, it accounts for the carbon footprint and shipping cost. Packaging companies in the U.S. are investing in research and development of smart packaging and increasing production capacity in response to this growth opportunity.

Sustainability regulation & smart packaging

The U.S. is tightening restrictions on single-use plastic and requiring the use of recyclable or compostable materials for primary packaging, giving brands a reason to include bioplastics and flexible packaging, as the next-generation packaging market is growing drastically and is driven by smart and eco-friendly packaging, one in which consumers want transparency in the packaging process and to learn about recyclability standards or supply-chain tracking from QR/ RFID codes. Collaborative alliances are beginning to form around eco-design standards and circular-economy systems to impact primary packaging areas. As an example of the tension in the market, Oroville Flexible Packaging made its Oroflex recyclable packaging available for use domestically in the U.S. in May 2024 for circular economy applications, claiming that domestic innovation would provide sustainable growth for the packaging industry.

WestRock, for instance, accomplished this with their QR-enabled pizza boxes, which educated consumers and enhanced circularity. With regulatory and consumer pressures, packaging companies are being asked to change production lines, invest in sustainable polymers, and implement traceability.

The growth of the U.S. primary packaging market is restrained by factors such as regulatory complexity & compliance costs and supply chain disruption, and material volatility in packaging.

Regulatory complexity & compliance costs

A foremost consideration in the market is the increasing complexity of U.S. primary packaging regulations. The federal and state requirements for single-use plastic bags, extended producer responsibility, and recyclability criteria in packaging define hurdles that responsibility demands companies to comply with, such as design iterations, material procurement, or packaging labeling. This is administratively heavy for smaller companies that are not equipped with either engineering or regulatory teams. Tracking the chains of custody for recycled content or confirming smart-label data adds even more complexity, and with the boom in smart labels or artificial intelligence-born data processes, the challenges and complexities are evolving in themselves. The inconsistency of state regulation makes this problem even worse (e.g., companies will most likely need to package differently based on region). Companies will likely need to manage all this while they are attempting to stay ahead of the relentless change in legislation.

Supply chain disruption and material volatility

One major challenge is the increasing complexity of U.S. packaging regulations. Federal and state rules related to bans on single-use plastic, extended producer responsibility, and legal standards for recyclability introduce compliance challenges that require rapid design changes and changes to materials or frequent updates to labels. All of these considerations are imposed upon individuals in an organization that likely does not have resources dedicated to engineering or regulatory teams. There is also a burden to manage chains of custody for recycled content and vet smart-label data, which all adds administrative burden. Differing rules at the state level add to the burden, where firms are not only facing differing requirements but also packaging for each state's regions. Legislative volatility will require ongoing monitoring and redesign, which extends the time-to-market process and diverts resources away from the innovation process. Such as the California SB 54 that mandates that 65% of plastic packaging is recycled or composted by 2032, as one example, firms are under relentless pressure as a designer/producer to keep up with materials continually changing.

The U.S. primary packaging market is going through a great deal of innovation, creating great opportunities for growth within our industry. The market itself is expanding to include smart and active packaging technologies such as packaging with embedded sensors, freshness indicators, interactive labels, real-time product quality, traceability, and safety, especially for expectations of transparency and health in the food and pharmaceutical areas. A further disruptor has been connections between packaging and artificial intelligence (AI), which has completely changed the way products are designed/ manufactured/ and even packaged. AI tools allow for days of predictive analysis for streamlining procurement, and various packaging to be customized based on consumer trends.

The onus on companies now is towards sustainability, including efforts to develop recyclable mono-materials (products made from a single type of material) and approaches towards packaging through a circular economy lens. The adoption of direct-to-consumer sales and e-commerce has led to an increase in interest in lightweight protective packaging to limit waste, while showcasing products. Government support for green infrastructure, coupled with interest in advanced manufacturing to drive the growth of next-generation packaging, is further legitimizing investments in this area. These developments position U.S. packaging companies to take a leading position globally within both sustainable innovation/ packaging and digital transformation, specifically within the primary packaging space.

“Oroflex is more than a plastics manufacturing and recycling company; we are partners in environmental stewardship. “Retailers, governments, and the public are increasingly demanding sustainable methods for producing and using plastic materials. We are dedicated to becoming the supplier of choice across the U.S. for comprehensive flexible packaging solutions to meet those demands.”

The bottles segment dominated the U.S. primary packaging market in 2024, prominently PET and HDPE bottles occupying the largest percentage of share compared to all other packaging types. Based on durability, resealability, and familiarity with consumers, bottles are used predominantly in food & beverage, personal care, and household-cleaning products. Bottles also held the largest value in terms of revenue in the pharmaceuticals sector in the U.S primary packaging market, which again confirms significant demand for liquid dosage forms. Given the number of advantages, such as scale of operations, acceptance from an FDA perspective, compatible with product pallets, and acceptance from customers, it is clear that bottles will continue to be the largest packaging type in primary packaging across many applications.

The pouch segment is anticipated to be the fastest-growing segment in the forecasted period as it is increasing in popularity across all segments, including food, beverage, and pharmaceutical markets. Pouches in North America were the highest growing flexible packaging format between 2025 and 2034 as a result of growing convenience and sustainability demand. In the U.S., the pouch packaging market was worth billions in 2024 and is forecasted to drastically increase, demonstrating a rapid uptake. Pouches are an excellent packaging method when made to be flexible with integrated spouts, resealable zippers, and lightweight, all while allowing consumers and customers to consume on the go and providing easy storage.

The food and beverage industry is the primary consumer of pouch packaging, with convenience food categories like ready-to-eat meals and frozen foods utilizing pouch formats because they allow control over portions and extending shelf-life like time and date-stamped frozen pork tenderloins. Also, in the pharmaceutical and personal care markets a barrier pouch format provides sterile and traceable packaging in a portable, low-cost structure. Pouches provide a combination of convenience with the sustainable environmental benefit created by lighter weight materials, and with the advances in barrier performance for pouches, making them rapidly become the fastest growing form of primary packaging in the U.S.

The plastic segment accounted for a considerable share of the market in 2024. Plastics such as PET, HDPE, and PP dominated the U.S. primary packaging market in 2024 due to lightweight, strength, and cost. In North America, followed by glass and paper cardboard, and plastic made up the highest material share for primary packaging in 2024, with the highest tonnage consumption in the U.S. The primary plastic container for pharmaceuticals had a remarkable share in North America, as noted by the common use of primary containers in syringes, vials, bottles, etc. The unique ability of plastics to allow a high rate of manufacturing and scalability, plus the availability of recycled-content material for both rPET and recycled PP, as well as compatibility for automation, all contributed to the strong position of plastics. Balancing product safety and protection, design flexibility, and logistical advantages especially in the high-volume markets has established the dominance of plastics in the U.S. primary packaging market.

The paper & cardboard segment is projected to experience the highest growth rate in the market between 2025 and 2034, enabled largely by sustainability mandates and consumer preferences. Emerging deployments of recyclable mono-materials within extended producer responsibility (EPR) frameworks like California's are increasing the demand for and acceptance of paper substrates, and they have prompted efforts that point to a continued increase in coated papers. In North America, throughout flexible packaging, bioplastics, and paper-based materials are growing rapidly and are often aligned with trends for sustainable designs. U.S. pouches have a growing percentage of paper-based constructions, initiated by converters' efforts to commit to lower plastic rummage content while ensuring adequate barrier performance. Considering everything, the intensifying regulatory pressures, consumer expectations, and innovations in packaging are accelerating the placement of paper and cardboard from "niche" formats into standard primary packaging channels in the U.S. primary packaging market rapidly.

The food & beverage segment dominated the primary packaging market as the market is supported heavily by the U.S. food & beverage sector, which has multiple formats of packaging with plastic bottles & containers, due to the strong reliance on packaging for bottled water, dairy, sauces, and oils, which contain food & beverages. Both rigid and flexible pouches representing convenience and portioning controls are gaining market adoption in the food & beverage sector, with additional format packaging being offered for ready-to-eat items or frozen items. Food safety regulations will always override the aesthetic elements and packaging solutions have been innovating with barrier films and also active packaging technology. Food & beverage has the highest volume of product in many formats, the highest investment, and the most technology development in primary packaging across the U.S.

The pharmaceuticals segment is set to experience the fastest rate of market growth from 2025 to 2034 thanks to booming demand for safe and regulated drug delivery systems. The sector is being driven by a huge increase in biologics and injectables, requiring more sterile and cold-chain compliant packaging. Smart packaging with RFID and temperature sensors is similarly on the rise in pharmaceuticals. The demand for contract manufacturing and packaging services in the U.S. is increasing at a rapid rate, while regulatory pressures around serialization and tamper evidence similarly serve to push companies toward advanced forms of primary packaging. With all of these trends combined, it is easy to see why pharmaceuticals are one of the fastest-developing and most specialized sectors in U.S. primary packaging.

The supermarkets segment captured a significant portion of the U.S. primary packaging market in 2024, as they are essential hubs for fast-moving consumer goods. Supermarkets have an expectation of shelf-ready designs that include defining features for branding and protection to reduce tampering risks, and design features that provide more convenience, such as resealable features and certain features that drive volume for bottles, pouches, cartons, and jars. Supermarkets must execute mass purchasing power with packages that can allow high-volume packaging runs in production to create efficiencies and reduce per‐item costs through consumption scale.

In addition, supermarkets are pushing sustainability and moving towards the recyclable nature of package materials, such as cardboard cartons and mono-material plastics. Lastly, because there is an aspirational goal of promotions, as well as growth in private label indicating supermarkets actionable goals for package design driven by customer behavior based on packaging, the supermarkets help packaging designers and innovators address potential packaging opportunities, issues, and innovations. Given that most U.S. packaged food and personal care product packaging will find its way through these distribution channels, we must view supermarkets as the main distribution channel for U.S. primary packaging.

The e-commerce segment is expected to grow at the fastest rate in the market during the forecast period of 2025 to 2034. The growing online retail industry has created an expectation among consumers to provide packaging that is lightweight, can withstand damage, and is environmentally responsible. As mentioned previously, flexible packaging, which includes pouches, is expected to grow the fastest in the U.S. in the packaging type insight due to e-commerce. This growth is mainly driven by demand for packaging that is easy to ship and has space-efficient formats. Pouch packaging, including both stand-up pouches and flat pouches, has been made to grab the attention of the consumer with compact formats that also offer protection through the supply chain and to the end user.

The innovations in materials consisting of mono-materials and recyclable barrier films align with consumer preference on the eco-end and also shrink costs during shipping. Also, using AI to make packaging decisions amongst fulfillment centers is creating efficiencies in going with the smallest size, thus generating less waste. As omni-channel retailing is on the rise, this distribution channel is changing the landscape of primary packaging preferences in the U.S. given the growing acceptance of flexible, sustainable forms of packaging.

The U.S. primary packaging market is highly competitive with companies globally competing through innovations and research and development of smart and sustainable packaging. Some of the key players in the market are Amcor Ltd., Bemis Company Inc., Capsugel Inc., Albea Group, Ardagh Group, Bormioli Rocco Spa, Clondalkin Group Holdings B.V., Datwyler Holding Inc., Gerresheimer AG, Heinz-Glas GmbH, and Wihuri Group.

There are many companies in the market but a few promising players in the market are:

Amcor is a packaging company in over 40 countries that provides flexible and rigid plastic, metal, and fiber-based food, beverage, pharma, and health care packaging solutions.

Berry Global is a packaging and engineering material company in over 50 countries, culminating in over 175 products for plastic packaging and engineered materials for the healthcare, food, and consumer waste management sectors.

WestRock is a leader in the packaging sector, supporting over 30 countries in the provision of paperboard, corrugated containers, folding cartons, and recycling solutions to the consumer goods and retail markets.

| Segments | Shares (%) |

| Bottles | 35% |

| Cans | 15% |

| Cartons | 18% |

| Pouches | 12% |

| Tetra Packs | 6% |

| Bag-in-Box | 8% |

| Kegs and Barrels | 6% |

| Segments | Shares (%) |

| Food & Beverage | 45% |

| Personal Care | 20% |

| Pharmaceuticals | 18% |

| Industrial | 17% |

| Segments | Shares (%) |

| Retail | 50% |

| E-commerce | 30% |

| Supermarkets | 20% |

Published by Vidyesh Swar

| Packaging Type | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bottles | 12.56 | 13.19 | 13.86 | 14.56 | 15.28 | 16.04 | 16.84 | 17.67 | 18.53 | 19.44 | 20.38 |

| Cans | 5.38 | 5.66 | 5.95 | 6.26 | 6.58 | 6.91 | 7.26 | 7.63 | 8.01 | 8.41 | 8.83 |

| Cartons | 6.46 | 6.77 | 7.09 | 7.43 | 7.78 | 8.15 | 8.52 | 8.92 | 9.33 | 9.75 | 10.19 |

| Pouches | 4.31 | 4.74 | 5.22 | 5.74 | 6.30 | 6.91 | 7.58 | 8.30 | 9.09 | 9.94 | 10.87 |

| Tetra Packs | 2.15 | 2.29 | 2.45 | 2.61 | 2.78 | 2.96 | 3.16 | 3.37 | 3.59 | 3.82 | 4.08 |

| Bag-in-Box | 2.87 | 3.10 | 3.34 | 3.61 | 3.89 | 4.20 | 4.53 | 4.88 | 5.26 | 5.67 | 6.11 |

| Kegs and Barrels | 2.15 | 2.49 | 2.85 | 3.26 | 3.71 | 4.20 | 4.74 | 5.33 | 5.98 | 6.69 | 7.47 |

| Application | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Food & Beverage | 16.15 | 17.10 | 18.10 | 19.16 | 20.29 | 21.47 | 22.73 | 24.06 | 25.47 | 26.96 | 28.53 |

| Personal Care | 7.18 | 7.73 | 8.32 | 8.95 | 9.63 | 10.37 | 11.16 | 12.00 | 12.91 | 13.89 | 14.94 |

| Pharmaceuticals | 6.46 | 7.04 | 7.66 | 8.34 | 9.08 | 9.87 | 10.73 | 11.67 | 12.67 | 13.76 | 14.94 |

| Industrial | 6.10 | 6.39 | 6.69 | 7.00 | 7.32 | 7.65 | 8.00 | 8.36 | 8.73 | 9.11 | 9.51 |

| Distribution | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Retail | 17.94 | 18.74 | 19.57 | 20.42 | 21.30 | 22.22 | 23.15 | 24.12 | 25.11 | 26.13 | 27.17 |

| E-commerce | 10.76 | 11.93 | 13.21 | 14.60 | 16.12 | 17.77 | 19.57 | 21.54 | 23.67 | 26.00 | 28.53 |

| Supermarkets | 7.18 | 7.57 | 7.99 | 8.43 | 8.89 | 9.38 | 9.89 | 10.43 | 11.00 | 11.60 | 12.23 |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Bottles | 12.56 | 13.19 | 13.86 | 14.56 | 15.28 | 16.04 | 16.84 | 17.67 | 18.53 | 19.44 | 20.38 |

| Cans | 5.38 | 5.66 | 5.95 | 6.26 | 6.58 | 6.91 | 7.26 | 7.63 | 8.01 | 8.41 | 8.83 |

| Cartons | 6.46 | 6.77 | 7.09 | 7.43 | 7.78 | 8.15 | 8.52 | 8.92 | 9.33 | 9.75 | 10.19 |

| Pouches | 4.31 | 4.74 | 5.22 | 5.74 | 6.30 | 6.91 | 7.58 | 8.30 | 9.09 | 9.94 | 10.87 |

| Tetra Packs | 2.15 | 2.29 | 2.45 | 2.61 | 2.78 | 2.96 | 3.16 | 3.37 | 3.59 | 3.82 | 4.08 |

| Bag-in-Box | 2.87 | 3.10 | 3.34 | 3.61 | 3.89 | 4.20 | 4.53 | 4.88 | 5.26 | 5.67 | 6.11 |

| Kegs and Barrels | 2.15 | 2.49 | 2.85 | 3.26 | 3.71 | 4.20 | 4.74 | 5.33 | 5.98 | 6.69 | 7.47 |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Food & Beverage | 16.15 | 17.10 | 18.10 | 19.16 | 20.29 | 21.47 | 22.73 | 24.06 | 25.47 | 26.96 | 28.53 |

| Personal Care | 7.18 | 7.73 | 8.32 | 8.95 | 9.63 | 10.37 | 11.16 | 12.00 | 12.91 | 13.89 | 14.94 |

| Pharmaceuticals | 6.46 | 7.04 | 7.66 | 8.34 | 9.08 | 9.87 | 10.73 | 11.67 | 12.67 | 13.76 | 14.94 |

| Industrial | 6.10 | 6.39 | 6.69 | 7.00 | 7.32 | 7.65 | 8.00 | 8.36 | 8.73 | 9.11 | 9.51 |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Retail | 17.94 | 18.74 | 19.57 | 20.42 | 21.30 | 22.22 | 23.15 | 24.12 | 25.11 | 26.13 | 27.17 |

| E-commerce | 10.76 | 11.93 | 13.21 | 14.60 | 16.12 | 17.77 | 19.57 | 21.54 | 23.67 | 26.00 | 28.53 |

| Supermarkets | 7.18 | 7.57 | 7.99 | 8.43 | 8.89 | 9.38 | 9.89 | 10.43 | 11.00 | 11.60 | 12.23 |

Demand is supported by increasing pharmaceutical output, expanding over-the-counter and specialty drug offerings, and the rise of personalized medicine. Consumer expectations for sustainable and interactive features, like smart labels and QR code traceability, are also accelerating innovation.

Bottles and blister strips remain the most widely deployed formats due to their versatility and manufacturing familiarity. Meanwhile, parenteral containers (e.g., vials and syringes) are the fastest-growing segment, propelled by injectable biologics and biosimilars.

Sustainability regulations and consumer eco-awareness are accelerating the adoption of recyclable, bio-based materials and mono-material flexible films. At the same time, food and drug safety regulations (e.g., child-resistant features, fair labeling) are demanding higher transparency and compliance.

Smart packaging technologies, such as NFC/RFID-enabled containers, digital traceability features, and smart blister packs, are transforming primary packaging into data-rich interfaces. Automation and quick-change fill lines support agility for diversified, personalized drug products.

Industry players contend with rising raw-material costs and trade-driven tariff impacts, particularly for metal and plastics. Additional challenges include long equipment replacement cycles, workforce needs for skilled operators, and investment requirements for sustainable and smart solutions.

To get full access to our Market Insights, you need a Professional Account or a Business Suite.

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Our customers work more efficiently and benefit from