By clicking “Accept All Cookies” you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

Privacy Policy

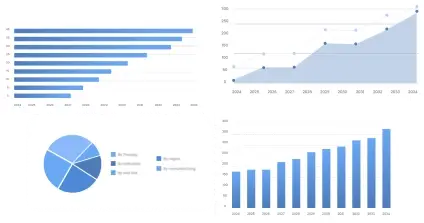

The global biopharmaceuticals manufacturing consumables testing market size accounted for USD 638 million in 2024 and is predicted to touch around USD 2,072 million by 2034, growing at a CAGR of 12.5% from 2025 to 2034.

| Industry Worth | Details |

| Market Size in 2025 | USD 718 Million |

| Market Size by 2034 | USD 2,072 Million |

| Market Growth Rate from 2025 to 2034 | CAGR of 12.5% |

The biopharmaceuticals manufacturing consumables testing market refers to the production, distribution, and application of biopharmaceutical manufacturing consumables testing, which is the process of evaluating the quality and performance of materials used in the production of biopharmaceuticals, such as bioreactors, filtration systems, and chromatography columns. The manufacturing process of biopharmaceuticals begins with upstream processing. This stage involves cultivating living cells that act as production factories for the desired therapeutic proteins. Cell culture techniques are employed to improve growth conditions and maximize protein production.

Biopharmaceuticals are generally protein agent substances derived from blood or blood products like proteins derived from animal sources, which are produced by genetically modified cell lines or monoclonal fully harmonized cytokines, antibodies, receptor proteins, chimeric proteins, or fusion proteins. These products support the analysis of complex biotherapeutic molecules and critical quality characteristics, making quality control and testing in biopharmaceutical manufacturing processes.

Rising R&D investments contribute to the growth of the biopharmaceuticals manufacturing consumables testing market. Investing in research and development (R&D) benefits include advancements in marketing abilities, cost management benefits, increased market participation, and trend-matching are all reasons companies invest in R&D. R&D drives innovation, improves competitive benefits, facilitates market expansion, and contributes to sustainable development. The benefits of investment research include more informed decision-making and risk mitigation. R&D is a significant long-term financial investment for companies, and it can also deliver many benefits besides increasing the availability of new products to the market.

R&D improves brand value, creates jobs, and raises national economic growth. R&D can generate revenue in different ways. R&D services can help companies innovate and develop new products, reduce costs, increase revenue, gain a competitive benefit, and achieve long-term success. By investing in R&D, businesses can stay ahead of the curve and continue to grow and prosper in the years to come. R&D benefits include generating innovative ideas and solutions to academic and societal problems. Modernizing the existing laboratories with additional experimental setups/instruments and technology for using the lab for research activity. Positive externalities occur when there is a positive gain on both the private and social levels. Research and development (R&D) conducted by a company can be a positive externality.

The rising prevalence of chronic diseases is driving the growth of the biopharmaceuticals manufacturing consumables testing market. Biopharmaceuticals can play an important role in prevention initiatives to reduce chronic disease. The benefits of biopharmaceuticals include global regulatory compliance, technological expertise, competitive pricing, biodegradability and eco-friendliness, reduced side effects, personalized medicine, increased efficacy, and precision and targeting.

Moreover, biopharmaceuticals contribute to patient care by guiding healthcare professionals in selecting the most appropriate drug products and dosing regimens for individual patients. Monoclonal antibodies (mAbs) are the largest class of biopharmaceuticals and are currently used in therapies for cancer, inflammatory diseases, cardiovascular diseases, infections, organ transplantations, infections, respiratory diseases, and ophthalmologic diseases.

Rising adoption of single-use technologies is driving the growth of the biopharmaceuticals manufacturing consumables testing market. Single-use assemblies reduce the risk of contamination by reducing the requirement for cleaning and sterilization procedures, which can act as potential sources of microbial and cross-product contamination. Each component is used only once and then discarded, ensuring a sterile environment for each production run. Single-use technology benefits include they can quickly be scaled up or down, enabling rapid changes in production volumes. In addition, disposable elements of single-use technologies can be quickly assembled and disassembled, reducing the amount of downtime needed for cleaning, sterilization, and maintenance.

Published by Ajit Bansod

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Laboratory Testing | - | - | - | - | - | - | - | - | - | - | - |

| Custom Testing / Customer Proprietary Testing | - | - | - | - | - | - | - | - | - | - | - |

| Compendial & Multi Compendial Laboratory Testing | - | - | - | - | - | - | - | - | - | - | - |

| Subsegment | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | 2032 | 2033 | 2034 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Formulation Excipients | - | - | - | - | - | - | - | - | - | - | - |

| Active Pharmaceutical Ingredients (API) | - | - | - | - | - | - | - | - | - | - | - |

| Compendial Methods (USP / EP / JP) Based Vendor Qualification Program Support | - | - | - | - | - | - | - | - | - | - | - |

To get full access to our Market Insights, you need a Professional Account or a Business Suite.

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Our customers work more efficiently and benefit from